Understanding ABS Filament for Tevo Tarantula

ABS (Acrylonitrile Butadiene Styrene) is a popular thermoplastic used in 3D printing for its durability, strength, and high-temperature resistance. However, printing with ABS on a Tevo Tarantula, or any open-frame 3D printer, presents unique challenges compared to materials like PLA. Understanding the properties of ABS filament and how it behaves during the printing process is the first step toward achieving successful prints. This guide will provide you with the necessary settings and troubleshooting tips to master ABS printing on your Tevo Tarantula and achieve the best results.

What is ABS Filament

ABS is a common thermoplastic polymer that is widely used in various industries due to its excellent mechanical properties. It is known for its impact resistance, toughness, and ability to withstand higher temperatures than PLA. ABS is a copolymer made from three monomers acrylonitrile, butadiene, and styrene, hence the name. This combination of materials gives ABS its unique characteristics, making it ideal for functional parts, durable prototypes, and items that may be exposed to heat or stress. Its ability to be easily machined and finished adds to its versatility.

ABS Filament Properties and Benefits

ABS offers several advantages, including its durability and resistance to higher temperatures, making it suitable for parts that will be used in environments where they could be exposed to heat or physical stress. It’s a robust material often used in automotive components, toys, and electronic housings. ABS is also relatively easy to post-process; it can be sanded, drilled, and painted, offering great flexibility in finishing your prints. Its ability to hold fine details and its resistance to certain chemicals further contribute to its appeal as a 3D printing material. Furthermore, ABS produces parts that are less brittle compared to some other filaments.

Why is ABS Difficult to Print

Despite its benefits, ABS presents some challenges during the 3D printing process. It tends to warp and shrink as it cools, which can lead to bed adhesion issues and dimensional inaccuracies. This warping is particularly pronounced with open-frame printers like the Tevo Tarantula, as the surrounding environment temperature directly affects the cooling of the print. ABS also emits fumes during printing, which can be unpleasant and potentially harmful if not handled properly. Controlling these factors requires precise settings and often the use of an enclosure to maintain a stable temperature during printing. Also, ABS can be more susceptible to cracking and layer separation if not printed at the correct temperature.

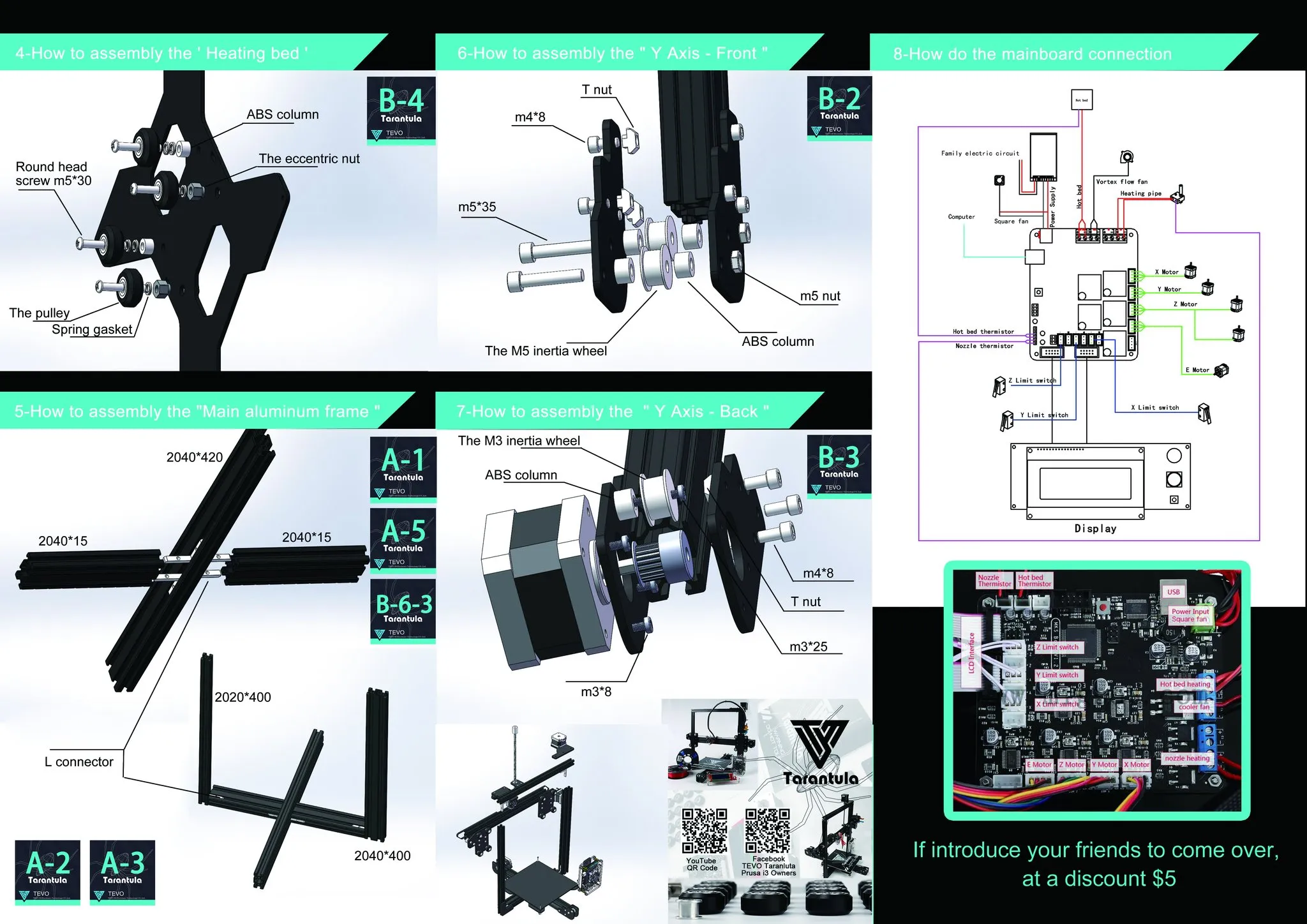

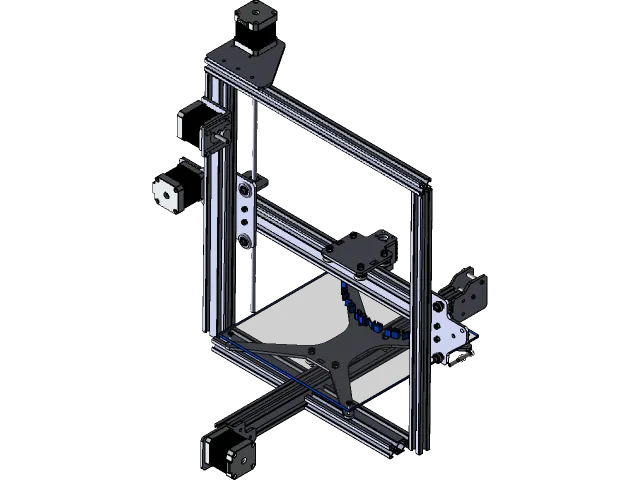

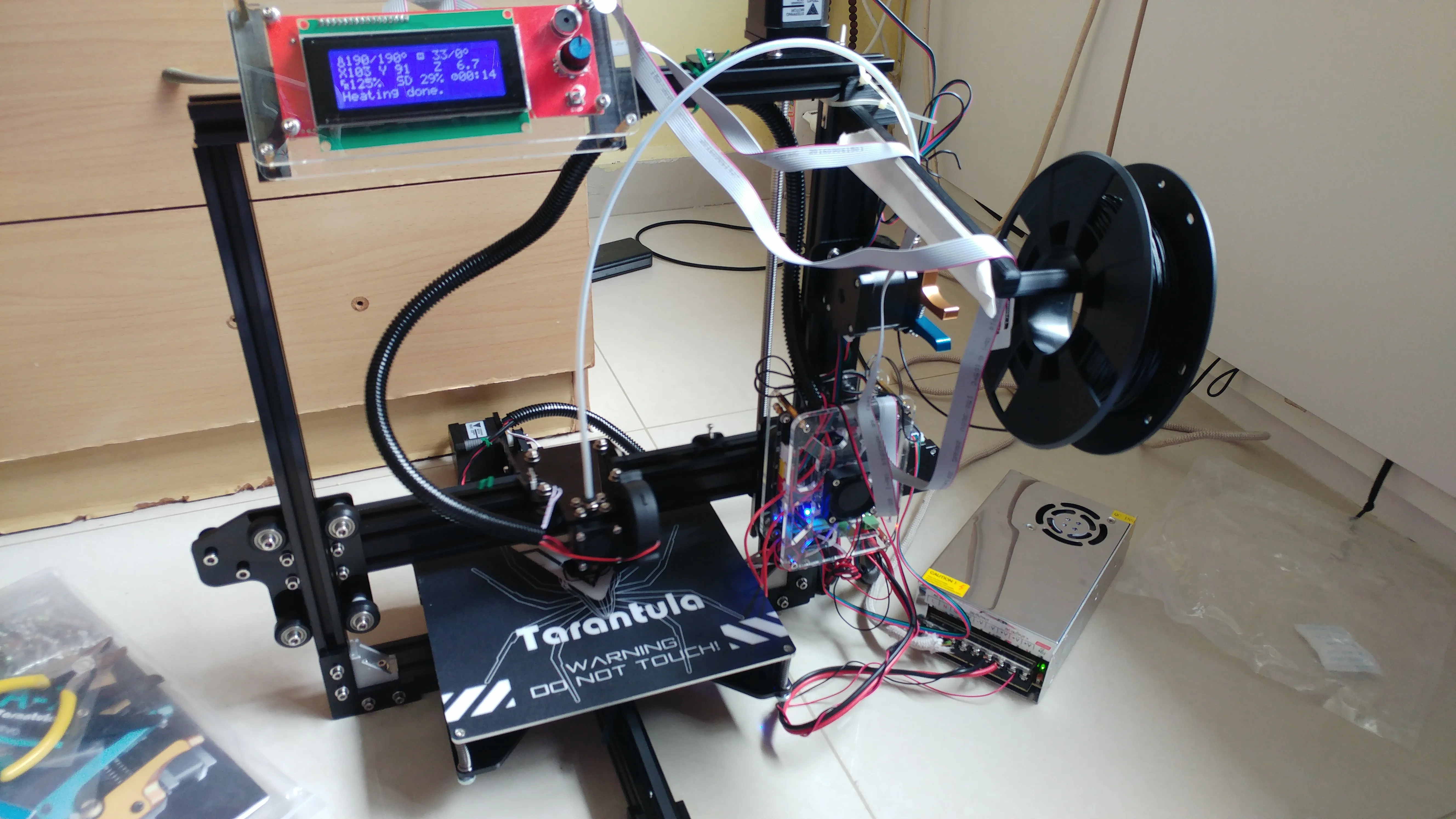

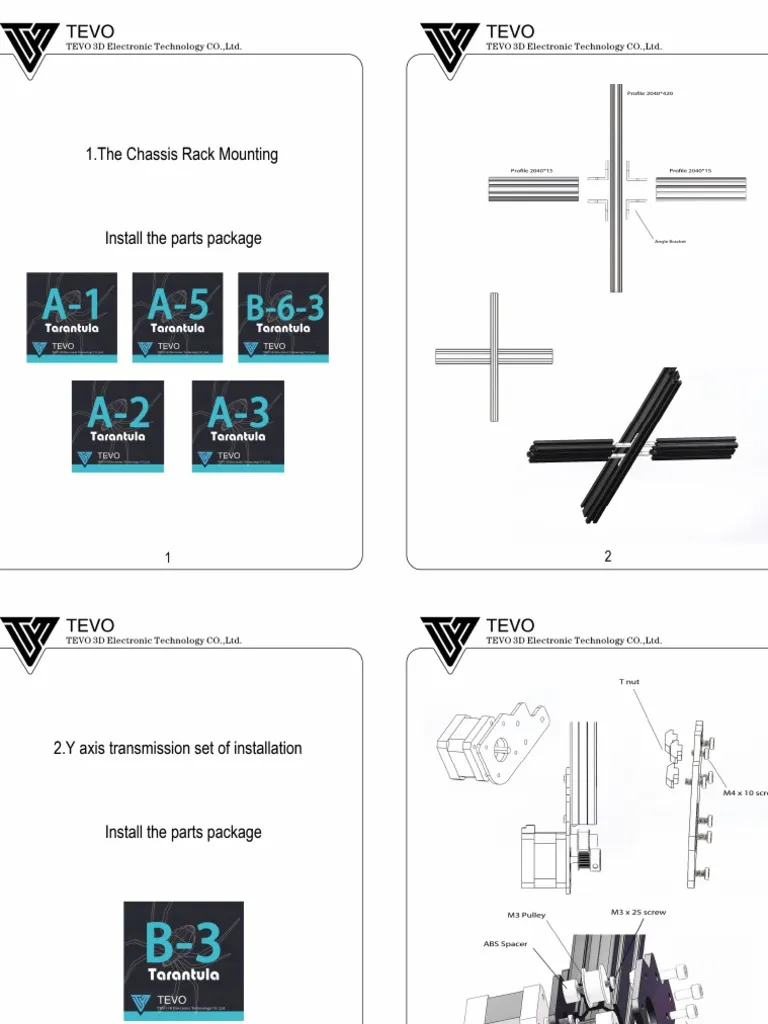

Preparing Your Tevo Tarantula for ABS Printing

Before starting an ABS print on your Tevo Tarantula, you need to prepare your printer for the material. This preparation is crucial for ensuring successful prints and mitigating the common problems associated with ABS. This involves several steps, including bed preparation, proper leveling, and, if possible, the use of an enclosure. Careful attention to these details will significantly improve your chances of producing high-quality ABS parts.

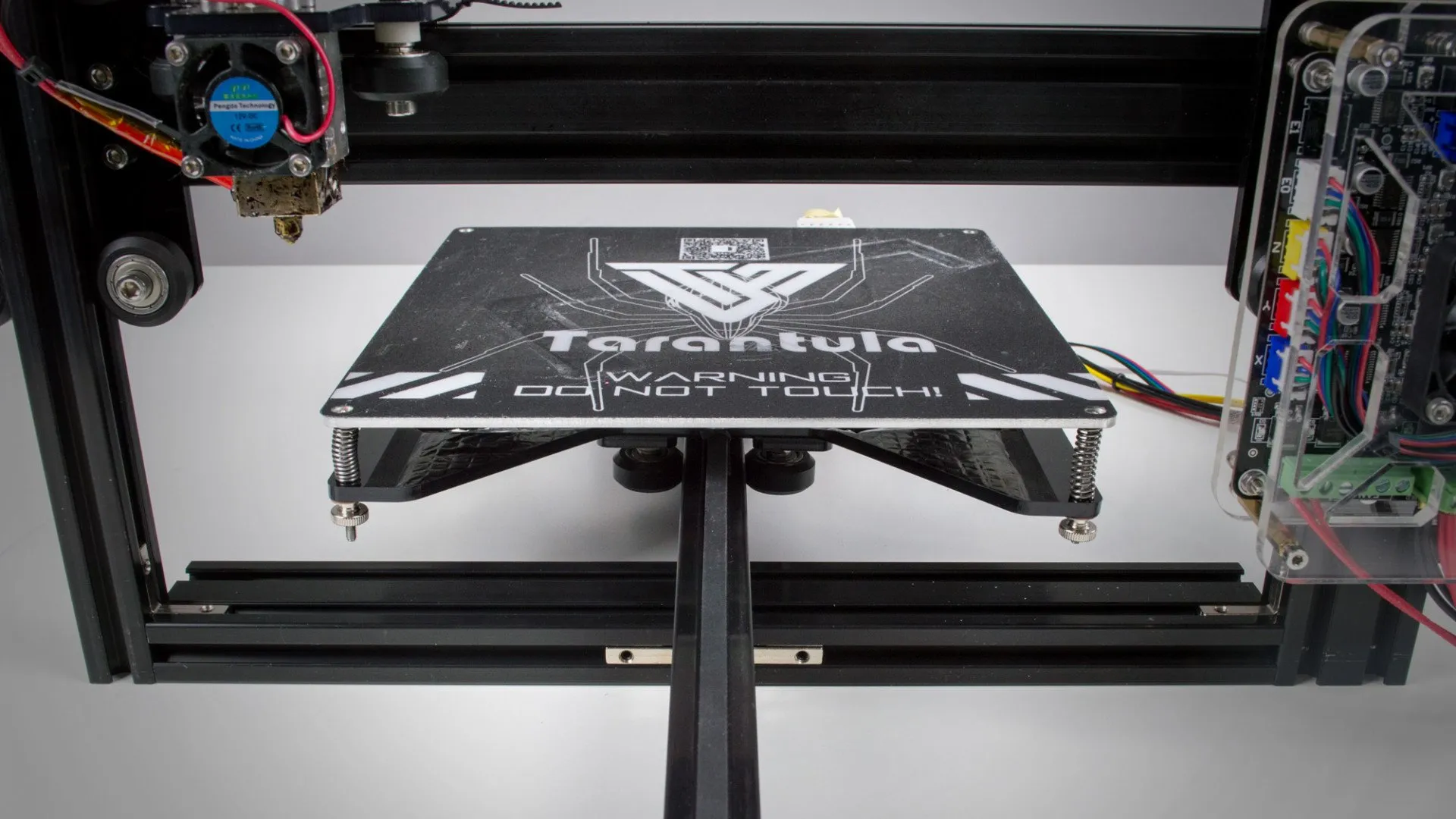

Bed Preparation & Adhesion Solutions

Good bed adhesion is essential for ABS printing to prevent warping. Several methods can improve adhesion on your Tevo Tarantula. Using a heated bed is crucial for ABS. Apply an adhesive to the bed surface. Some common options include ABS slurry (ABS dissolved in acetone), hairspray, or specialized 3D printing bed adhesives. Ensure the bed is clean and free of any oils or debris before applying the adhesive. The bed surface should be leveled carefully, with the nozzle at the correct height to ensure the first layer properly bonds to the bed surface. Consider using blue painter’s tape or Kapton tape on the bed surface to provide a better surface for the ABS to adhere to. This can help the first layer stick more securely.

Leveling the Bed and First Layer

Accurate bed leveling is critical for ABS printing success. A bed that is not properly leveled will lead to poor first-layer adhesion, warping, and other printing issues. Ensure the nozzle is the correct distance from the bed across the entire printing surface. Most Tevo Tarantulas can be leveled manually using the adjustment screws at the corners of the bed. Use a piece of paper to check the nozzle height, ensuring there is slight resistance when sliding the paper between the nozzle and the bed. Adjust the bed height at each corner until the nozzle is consistently at the correct height across the bed. Once the bed is level, adjust the Z-offset to fine-tune the first layer, ensuring the filament is properly squished onto the bed without the nozzle being too close or too far away.

Enclosure Options for ABS Printing

An enclosure is highly recommended when printing with ABS on a Tevo Tarantula. An enclosure helps to maintain a consistent temperature around the print, reducing warping and improving layer adhesion. You can create a simple enclosure using materials like cardboard, acrylic panels, or even a repurposed cabinet. Enclosures help to reduce drafts, which can cause uneven cooling. Ensure the enclosure is well-ventilated to prevent the buildup of fumes. Monitor the temperature inside the enclosure during printing to ensure it is within the optimal range for ABS. Consider adding a temperature sensor to monitor the environment inside the enclosure during the print. A stable internal environment contributes significantly to successful ABS prints.

Optimal Tevo Tarantula ABS Settings

Finding the right settings for ABS on your Tevo Tarantula is a process of experimentation, but there are some general guidelines to start with. Several factors influence print quality, including nozzle temperature, bed temperature, print speed, and retraction settings. These parameters must be optimized to achieve the best results. The following settings are a starting point; you may need to fine-tune them based on your specific filament and printer setup. Always start with small test prints before printing larger, more complex objects to ensure the settings work well.

Nozzle Temperature and Recommendations

The nozzle temperature is critical for melting the ABS filament properly. The ideal nozzle temperature for ABS typically ranges from 230°C to 250°C, but the exact temperature will depend on the specific brand and color of your filament. Start with the manufacturer’s recommended temperature and adjust it in 5°C increments. If the filament isn’t extruding smoothly, increase the temperature. If you see excessive stringing or oozing, reduce the temperature slightly. A slightly higher temperature often improves layer adhesion, while a lower temperature reduces stringing. Conduct temperature tests to identify the optimal temperature for your specific filament and printer configuration. Observe the extruded filament for consistency and adhesion during the test.

Bed Temperature and Its Impact

A heated bed is essential for ABS printing to promote bed adhesion and reduce warping. The optimal bed temperature for ABS usually ranges from 90°C to 110°C. This higher temperature helps to keep the first layer from lifting off the bed as it cools. Adjust the bed temperature in small increments to find the best setting for your filament and bed surface. For better adhesion, you may need to increase the bed temperature slightly. However, avoid excessively high bed temperatures, as this can cause the bottom layers to become overly soft and deform. Maintaining the correct bed temperature is crucial for preventing warping, ensuring the first layer adheres properly to the bed, and for reducing stress in the final print.

Print Speed and Layer Height Optimization

Print speed and layer height impact the print quality and the likelihood of warping and other issues. ABS generally benefits from slower print speeds. A print speed between 30mm/s and 60mm/s is usually recommended for ABS on a Tevo Tarantula. Lower speeds allow the layers to bond properly and reduce the chances of warping. The layer height setting can also affect the quality of the print. For optimal results, use a layer height between 0.1mm and 0.3mm. Finer layer heights (e.g., 0.1mm - 0.2mm) result in smoother surface finishes and higher resolution, but they also increase the print time. For faster prints, you can use a slightly larger layer height (e.g., 0.25mm - 0.3mm). Test different combinations of print speed and layer height to find the settings that work best for your prints.

Retraction Settings for Best Results

Retraction settings are crucial to control stringing and oozing, common problems with ABS. Retraction pulls the filament back into the nozzle when the printer moves to a new location. The recommended retraction settings for the Tevo Tarantula and ABS generally include a retraction distance between 3mm and 6mm and a retraction speed between 25mm/s and 45mm/s. The exact settings can vary depending on your printer and filament. Adjust the retraction distance and speed in small increments. If you see stringing, increase the retraction distance slightly. If the nozzle is clogging, decrease the retraction distance. Experimenting with retraction settings and fine-tuning them can dramatically improve the appearance of your prints.

Cooling Fan Settings for ABS

Unlike PLA, ABS typically benefits from minimal cooling fan usage. Too much cooling can cause warping and layer separation. Disable the cooling fan for the first few layers to ensure good bed adhesion. After the first few layers, you can enable the cooling fan at a very low setting, typically between 10% and 20%, to help control the temperature of the print. Adjust the fan speed based on the print results. If you see warping, reduce or disable the cooling fan. If you see overhangs sagging, you can increase the fan speed slightly. The goal is to balance cooling to prevent warping without causing layer separation or compromising part strength.

Troubleshooting Common ABS Printing Problems

Despite the best settings, you may encounter problems when printing with ABS. Knowing how to diagnose and fix these issues is crucial to achieve high-quality prints. Many common problems can be resolved by adjusting settings or making small modifications to your printer setup. This section will address some of the most frequent problems encountered with ABS printing and suggest solutions.

Warping Issues and Solutions

Warping is one of the most common problems when printing with ABS. Warping occurs when the edges of the print lift off the bed. To minimize warping, ensure proper bed adhesion. Use a heated bed with the correct temperature, and use an adhesive. An enclosure is essential for ABS to maintain a stable temperature around the print. Reduce the cooling fan speed, or turn it off for the first few layers. Level your bed accurately to ensure the first layer adheres properly. For large prints, you can also use a brim or raft to increase the contact surface area with the bed and prevent warping.

Cracking and Layer Separation Troubleshooting

Cracking and layer separation occur when the layers of the print do not bond together properly, or the part cools too quickly. Increase the nozzle temperature to improve layer adhesion. Ensure your printer is printing within an enclosure to maintain a consistent temperature, especially for tall or complex models. Reduce the print speed to allow each layer to bond properly. Avoid excessive cooling, as this can cause the layers to cool too quickly. If the issue persists, consider drying your filament, as moisture can affect the bonding of layers.

Poor Bed Adhesion

Poor bed adhesion is a common problem that leads to failed prints. Ensure your bed is properly leveled, as an unleveled bed is a frequent cause of adhesion problems. Clean your bed surface to remove any oils or debris. Use a bed adhesive, such as ABS slurry, hairspray, or a dedicated 3D printing glue. Increase the bed temperature to the recommended range for ABS. Make sure the first layer is properly squished onto the bed, ensuring good contact. If using a brim, make sure it’s wide enough to ensure sufficient contact area for the model to stick.

Stringing and Blobs Prevention

Stringing and blobs are caused by filament oozing from the nozzle during travel moves. Optimize your retraction settings. Increase the retraction distance slightly and adjust the retraction speed. Reduce the nozzle temperature, but ensure proper layer adhesion. Ensure your filament is dry, as moisture can cause stringing. Increase travel speed to minimize the time the nozzle spends traveling between points. Make sure your printer is properly calibrated to help reduce these issues.

Post-Processing ABS Prints

After your ABS print is complete, there are several post-processing steps you can take to improve its appearance and functionality. ABS is well-suited to post-processing techniques like sanding, gluing, and painting. These methods can refine the surface finish, repair imperfections, and enhance the overall quality of your prints.

Sanding and Smoothing ABS Prints

Sanding is a common method to smooth ABS prints and remove layer lines and imperfections. Start with coarse grit sandpaper (e.g., 120-220 grit) to remove major imperfections and layer lines. Gradually move to finer grits (e.g., 320, 400, 600, and higher) to refine the surface and achieve a smooth finish. Use a sanding block to ensure even sanding. For complex shapes, consider using wet sanding, which helps to reduce clogging and produces a smoother result. After sanding, you can use a polishing compound to further enhance the surface finish. Be sure to wear appropriate safety gear, such as a dust mask, when sanding.

Gluing ABS Parts

ABS can be easily glued using various adhesives. Cyanoacrylate glue (super glue) works well, providing a strong bond. Apply the glue to the surfaces to be joined and hold them together until the glue sets. ABS cement, made by dissolving ABS in acetone, creates a chemical bond that melts the surfaces of the parts together for a permanent bond. This is a good option for parts that need to be extremely strong. Ensure the surfaces are clean and dry before gluing for best results. Use clamps to hold the parts together while the glue cures.

Painting ABS Prints

ABS is an excellent material for painting, as it readily accepts paint. Clean the print thoroughly to remove any dust or grease. Use a primer designed for plastics to improve paint adhesion. Apply several thin coats of primer, allowing each coat to dry before applying the next. Once the primer is dry, you can apply your chosen paint. Acrylic paints are a popular choice. Apply multiple thin coats of paint to achieve a smooth, even finish. After the paint has dried completely, you can apply a clear sealant to protect the paint and enhance its durability. Be sure to work in a well-ventilated area and wear appropriate safety gear.