Understanding Flexible Filament and the Tevo Tarantula

The Tevo Tarantula is a popular and affordable 3D printer, known for its versatility and ease of use. However, to unlock its full potential, especially when printing with flexible filaments, a bit of understanding and preparation is required. Flexible filaments, unlike the rigid PLA or ABS, offer a unique set of properties, including elasticity and durability, opening up a world of possibilities for your 3D printing projects. Successfully printing with flexible filament on the Tevo Tarantula requires careful consideration of various factors, including printer settings, filament selection, and post-processing techniques. This guide will provide you with the essential tips to master flexible filament printing and achieve outstanding results with your Tevo Tarantula.

What is Flexible Filament?

Flexible filaments are thermoplastic materials that exhibit rubber-like properties, allowing them to bend and flex without breaking. They are made from materials like TPU (Thermoplastic Polyurethane), TPE (Thermoplastic Elastomer), and others. The flexibility of these filaments is measured by their Shore hardness, a scale that indicates the material’s resistance to indentation. The lower the Shore hardness, the more flexible the filament. These materials are ideal for creating parts that need to be soft, resilient, and able to withstand impact, such as phone cases, seals, and even tires for small RC cars. Their ability to deform and return to their original shape makes them excellent for various applications where traditional filaments would be too brittle.

Why Use Flexible Filament with Tevo Tarantula?

The Tevo Tarantula, with its open-frame design and accessible features, is a great machine to experiment with flexible filaments. This printer can be modified and tweaked to print these special materials. Furthermore, the printer’s relatively low cost makes it an ideal choice for hobbyists and beginners who want to explore the possibilities of flexible filament printing without a significant investment. The ability to print flexible materials expands the range of projects the Tevo Tarantula can handle, from functional prototypes to artistic creations. With the correct adjustments and settings, the Tevo Tarantula can deliver impressive results with flexible filaments, letting you bring your unique ideas to life.

Tip 1 Prepare Your Tevo Tarantula

Before attempting to print with flexible filament, it’s crucial to ensure your Tevo Tarantula is properly prepared. This involves several key adjustments to optimize the printing experience. Preparing your printer correctly helps minimize common issues like filament jams, poor adhesion, and inconsistent extrusion. This preparation phase sets the foundation for successful flexible filament printing, ensuring that your prints come out as intended.

Leveling the Bed

Proper bed leveling is the cornerstone of any successful 3D print, and it’s particularly important when working with flexible filaments. Ensure the print bed is perfectly level to achieve optimal first-layer adhesion. A properly leveled bed ensures that the filament adheres correctly to the build surface, preventing warping and improving overall print quality. Use the paper test or auto-leveling features (if available) to ensure a consistent distance between the nozzle and the bed across the entire printing surface. This step is crucial for the first layer and sets the foundation for the rest of your print.

Adjusting Nozzle Temperature

Flexible filaments typically require a different temperature range than PLA or ABS. Consult the filament manufacturer’s recommendations for the ideal nozzle temperature for your chosen filament. Start with the recommended temperature and make small adjustments based on the print quality. If the filament isn’t extruding smoothly or the print layers aren’t adhering, slightly increase the nozzle temperature. Conversely, if the filament is oozing or stringing, slightly decrease the temperature. Fine-tuning the nozzle temperature is crucial for achieving the desired print quality and avoiding issues like under-extrusion or excessive stringing.

Tip 2 Choosing the Right Flexible Filament

Selecting the correct flexible filament is the key to success. Not all flexible filaments are created equal, and some are easier to print with than others. Understanding the different types and their properties will help you choose the best filament for your project. Several brands produce flexible filaments, and it’s worth experimenting to find the one that works best with your Tevo Tarantula and your specific needs. Always store your flexible filaments in a dry place to prevent moisture absorption, which can negatively affect print quality.

Types of Flexible Filament

TPU is the most common type of flexible filament, known for its excellent elasticity and durability. It’s a good all-around choice for various applications. TPE is another popular option, offering a wider range of flexibility and often being easier to print than TPU. Other specialized flexible filaments are available, each with unique properties, like higher temperature resistance or improved abrasion resistance. The choice of filament should be based on the specific requirements of your project and the desired mechanical properties of the final printed part.

Shore Hardness Explained

Shore hardness is a scale that measures the flexibility of a material. It’s crucial to consider the Shore hardness rating when choosing a flexible filament. The lower the Shore hardness, the more flexible the filament will be. Filament with a Shore hardness of 95A or less is generally considered to be very flexible. Higher hardness ratings will produce parts that are less flexible and more rigid. The Shore hardness directly impacts the material’s ability to bend and stretch, making it a critical factor in the selection process.

Tip 3 Printing Speed & Settings for Flexible Filament

Printing with flexible filament requires a different approach compared to rigid filaments. Slowing down the print speed and adjusting various settings is essential for preventing jams and achieving optimal print quality. This section details the optimal print speed and retraction settings for your Tevo Tarantula, allowing you to master flexible filament printing.

Print Speed Optimization

Printing at a slower speed is one of the most crucial adjustments for flexible filament. Start with a print speed of 20-30 mm/s and gradually increase it if the print quality allows. Flexible filaments can be prone to buckling and jamming if pushed through the hot end too quickly. Slowing down the print speed allows the filament to melt and extrude smoothly, reducing the risk of print failures. Fine-tuning the print speed is an iterative process, and it’s best to experiment to find the optimal speed for your specific filament and project.

Retraction Settings

Retraction settings are critical for preventing stringing and oozing when printing with flexible filament. Generally, you’ll want to reduce the retraction distance and slow down the retraction speed. Start with a retraction distance of 1-2 mm and a retraction speed of 20-30 mm/s. Too much retraction can cause the flexible filament to pull back too far, leading to jams. Fine-tune these settings through print tests to find the perfect balance between preventing stringing and ensuring proper extrusion. Retraction settings are often a significant factor in the overall print quality.

Tip 4 Extruder Adjustments for Flexible Filament

The extruder plays a vital role in the printing process. This section offers information about how to make the necessary adjustments to your extruder setup to ensure the flexible filament feeds smoothly and consistently. Attention to the extruder is essential for achieving a flawless print.

Extruder Gear Tension

Proper extruder gear tension is important for flexible filament. If the tension is too loose, the filament may slip, leading to under-extrusion. If the tension is too tight, the filament could be compressed or even damaged, which can cause jams. Adjust the extruder gear tension to provide a firm grip on the filament without deforming it. The correct tension allows the extruder to reliably push the flexible filament through the hot end without problems. Experiment with the tension to find the sweet spot.

Direct Drive vs Bowden Extruder

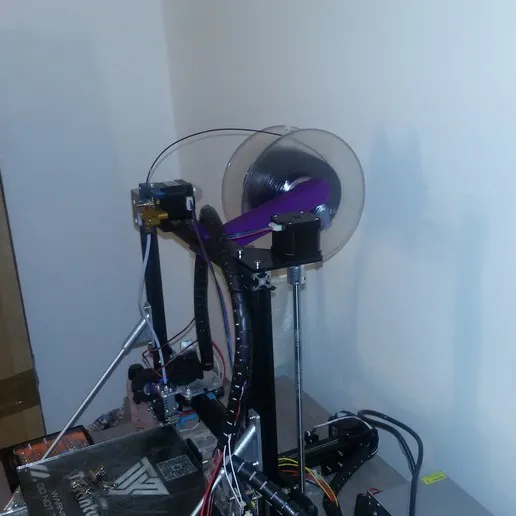

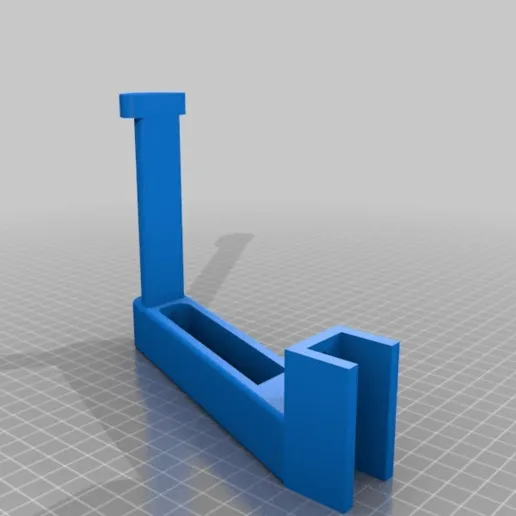

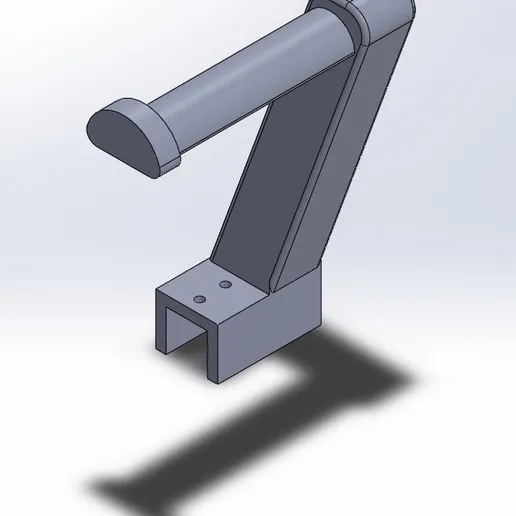

The Tevo Tarantula, like many 3D printers, typically has a Bowden extruder setup. The Bowden system can present challenges with flexible filaments due to the distance between the extruder and the hot end. A direct drive extruder, where the extruder is mounted directly above the hot end, can be better suited for flexible filament printing. A direct drive setup minimizes the distance the filament needs to travel, reducing the chances of buckling and improving print quality. Consider upgrading to a direct drive extruder for easier and more reliable flexible filament printing. If you have a Bowden extruder, ensure that the PTFE tube is tightly fitted and in good condition, as this can affect print quality.

Tip 5 Post-Processing and Applications

Once your flexible filament print is complete, there are some important steps for post-processing. These steps will help you optimize the final result. This section discusses how to handle support structures and gives you an overview of applications of flexible filament.

Removing Support Structures

Support structures are often necessary when printing complex geometries with flexible filament. Carefully remove support structures to prevent damage to the flexible print. Depending on the filament, you may need to use tools like flush cutters or a hobby knife to remove supports. Try to position supports in areas where they are easier to remove and less likely to leave marks. Remember to be gentle when removing support structures, as flexible filaments can be more prone to tearing than rigid filaments.

Applications of Flexible Filament Prints

Flexible filaments offer many creative and functional applications. From phone cases and protective covers to grips, seals, and custom RC car tires, the possibilities are vast. They are ideal for printing items that need to be impact-resistant, flexible, or have a rubber-like feel. With the proper settings and preparation, you can create all sorts of products. Experiment with different designs and applications to realize the full potential of flexible filament with your Tevo Tarantula. There’s a wealth of projects to explore, making flexible filaments a valuable addition to your 3D printing capabilities.